Top 10 Things You Didn’t Know Your Makerspace Needs

Some makerspace components are so commonly known that I can even use them to explain my job to non-educators:

“I’m our makerspace coordinator. You know, the person who supports the kids with 3D printing and basic electronics and stuff like that.”

Then they know exactly what I mean. (I can tell because they respond with “Wow! That sounds like the best job ever!” They’re right!)

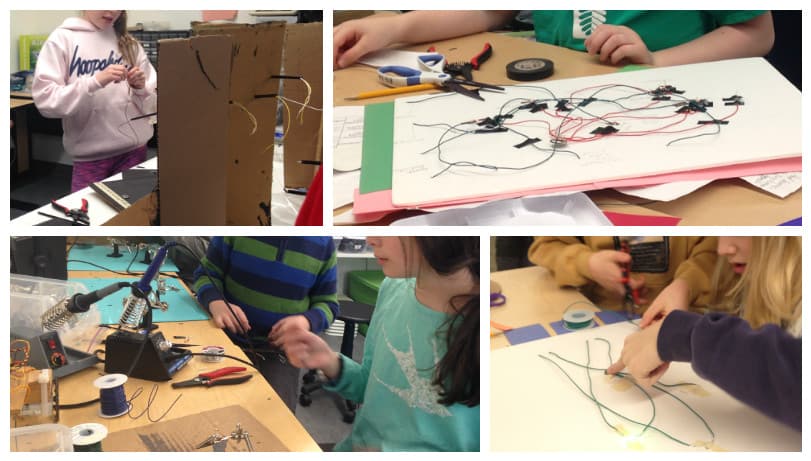

Educators planning makerspaces know they can start small with simple circuitry materials, cardboard and hot glue guns. Or they can go bigger with soldering capabilities and power drills. Or they can go to the biggest with 3D printers and laser cutters.

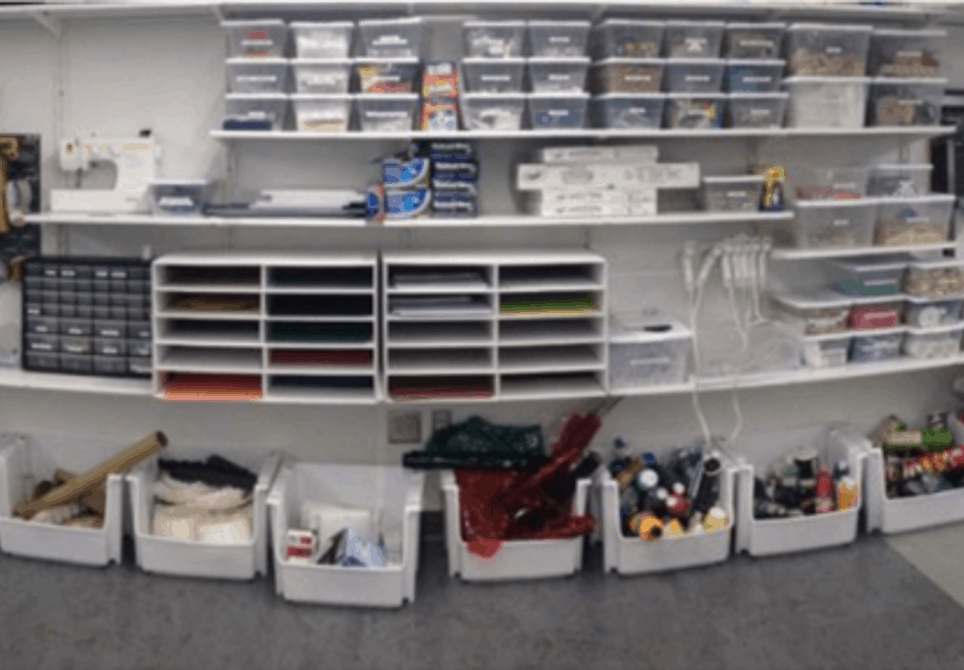

For makerspaces incorporating digital technology, a green screen and an iPad with green screen apps are no-brainers, whether they go for a green bedsheet or a fancy installation. Whiteboard tables are widely known to be hot, as well as clear bins and neutral organization, pegboard and labels, craft sticks and straws and velcro tape.

The level of sophistication/extravagance of the space will vary enormously depending on each institution’s choices and funding ($20K Epilog or $5K Glowforge or no laser cutter?), but there were a few surprises as we developed our space, noticing or finding unexpectedly critical makerspace components that have made our space more successful.

Here are our top 10 unexpectedly critical makerspace components, clickbait countdown style!

10) Materials From Home: Cereal Boxes

You probably already know that you need packing boxes. Hefty corrugated cardboard is like gold in a makerspace, but lightweight cereal box cardboard is even better for many applications.

Cereal box cardboard is nice and stiff, but still easy to cut with basic scissors. It also cuts and engraves beautifully in the laser cutter. Boxes that are white cardboard on the inside are particularly prized. Families at our school responded in droves to my call for their empty cereal boxes, and with a bit of training–don’t fold up and bend the cardboard to make it “easier” to store, don’t bother with boxes that have cut-outs–we’ve build up a significant supply of cardboard that kids can pillage as needed.

9) Materials From Home: Corks

Corks are a popular material in general crafting circles. Probably everyone has seen a Pinterest picture of a home corkboard made from actual corks. I included corks in my all-call for materials from families thinking they would just be handy to have around, but I’ve been astonished at how heavily the kids use them for their various building projects: columns for Greek temples, bodies and heads for oxen pulling Oregon Trail wagons, backings for pins sticking through posters, etc. I’ve had to issue a second all-call for corks to replenish our supply from the beginning of the year, and luckily many families had gotten into the habit of saving their corks!

Of course, there are dozens of other materials that are valuable to have families bring from home: toilet paper and paper towel rolls, egg cartons, shoeboxes and plenty more. Cereal boxes and corks have been our biggest surprises, and so our biggest needs!

8) “Monster Scissors“

“Craft Cutter” is such an absurd and generic name for these scissors. At some point, I said to a kiddo, “Grab those big blue-handled huge scissors…the monster scissors!” and the name stuck. With a very heavy-duty blade and a built-in protractor to check your cutting angles, these scissors snap right through craft sticks, skewers, chopsticks and our beloved corks. They have a safety latch and are easy for upper-elementary kids and above to use.

7) Electric Cardboard Cutter

Like the Monster Scissors, these cutters prove that even your basic titanium scissors are NOT all-purpose tools–sometimes a different cutting tool is needed. The electric cardboard cutters make incredible fast work of deconstructing corrugated cardboard boxes into smaller sizes to use as building bases, to fit into the laser cutter or even just to get to a smaller, more-easily-manipulatable size for further cutting with normal scissors. There have been times when I unexpectedly ran out of project “bases” and churned out another 20 from whole cardboard boxes in less than two minutes.

6) Pre-cut Cardboard Pieces Library

With all that cardboard, kids might spend hours and hours just trying to cut the simple shapes needed for their projects. 90% of the time kids need to do that sort of dirty work themselves, but when it comes to plain cardboard squares I’d rather the kids use their time building and adjusting a stable structure than trying to cut a just-right square of cardboard. So we keep a library of project “bases”–flat pieces of corrugated cardboard about 30cm x 15cm–as well as small (5-10 cm) basic shapes like circles, squares and triangles that kids can snag as needed. We also keep a library of basic gears designed on geargenerator.com!

This is an area where a laser cutter comes in incredibly handy. We can churn out bins full of our library of shapes in about an hour. In the absence of a laser cutter, it would be hard to produce circles or gears, but the electric cardboard cutters would greatly simplify churning out squares and triangles.

5) A Wind Tunnel

If this feels sort of silly and random, that’s because it is! A student built a PVC-pipe-and-plastic-sheet windtunnel for a science project last year, and I’m so glad we held on to it. Testing in most design scenarios is pretty hard for any conditions other than a”typical room” (or if we’re lucky, “whatever the weather is outside”). But we’ve already used the wind tunnel for two different projects, and I anticipate using it more as we develop more opportunities for design, testing and iteration. We also have a very large sink that we use as a testing environment, and I hope we’ll be able to add others. A hot box? What else?

4) Giant Spools of Cat5 Ethernet Cable

This is a hack stolen directly from my husband’s electronics prototyping lab. Spools of insulated wire are expensive and it’s easy for a class of 20-30 kids to go through a 100 foot spool in one class period. But a 1,000 foot bulk spool of cat5 cable costs only about three times what a 100 foot spool of typical stranded hook-up wire. That 1,000 feet of cat5 actually contains 8,000 feet of wire. That’s not a typo: Eight Thousand Feet!

Because cat5 wire is comprised of eight twisted strands of pretty high-gauge (thin) wire, you can easily strip off the outer plastic jacket to remove whatever lengths of (color-coded) wire are inside. Stranded and solid-core cat5 are both available on Amazon. Stranded wire is generally more flexible, and I’ve found it to be easier for kids to manipulate.

This is a HUGE money saving hack!

3) Google Drive (and a general account dedicated for the makerspace)

Files being sent for laser cutting, photos and videos collected, 3D files awaiting slicing…a lot of digital fabrication means a lot of file transfer. For our iPad Minis in particular, having a dedicated Google Drive account for our makerspace has been critical. Our iPad Minis stay logged in to that account, and students upload their “Garage Band” recordings, green screened photos and videos, and other digital resources from the iPad directly to that Google account, and then share it with their own Google accounts. (Yes, we’re a GAFE school.)

This way, kids don’t need to log in or out of their own accounts on the iPads. They can upload and share laser cutting files that are then accessible to any of the teachers who operate the laser cutter, and I have a base email address for creating communal accounts on programs like Scratch or Tinkercad.

2) A Wall-Mount Drying Rack

Cable management is a nightmare, and there are lots of solutions on the market and hacks on Pinterest for managing all the various wires that are needed in working with electronics. But alligator clip jumper wires are in a special category all on their own. They’re in constant use, moving in and out of projects, are delicate (kids yank off the alligator clips easily) and get hung up on each other. Here’s where a drying rack comes in.

When I visited Adrienne Gifford’s fantastic space at Open Window School on the east side of the Seattle metro area, I spotted her brilliant solution of hanging alligator clip wires from a clothesline. We took this idea one step further (and denser!) and incorporated a drying rack into the IKEA shelving system we used for our general storage. Clipping the alligator clips onto the rack rails keeps them organized, un-knotted, easily accessible and has the ultra bonus of adding some nice color to the wall-o-bins.

1) A Mantra/Shared Vocabulary/Shared Expectations

Like I mentioned in my earlier post on makerspace leadership, our big “rules” of the makerspace arose somewhat organically/reactionarily, and I wish I’d thought that need through more ahead of time. We had clear rules like “Must Wear Safety Glasses In The Woodworking Room” and “No Supermanning On The Rolling Chairs,” but we were lacking the more cognitive rules around trying and what “help” looks like. What arose was:

- You have to try. And when it doesn’t work, just try again.

- “Help” doesn’t mean “do it for you.”

These just arose, sort of in the same way the term “Monster Scissors” arose. I said them a few times and they stuck. And I don’t think “that’s what stuck” is the best way to establish kid-friendly common language around habits of mind.

Given another shot at launching a makerspace, I might try to use introductory projects as opportunities to more explicitly explore and reflect on the habits of mind growth in a makerspace.I would introduce the ideas of perseverance and independence before starting the projects rather than only in response as I run into “requests for help” that are actually a kiddo trying to give me their materials to do for them.

Although, maybe not. Maybe introducing those ideas in response was a more effective way for the kids to absorb it? In any case, the kids are now only rarely “helping” their friends by doing whatever task for them! Now that we have that mantra, it gives teachers, other adults and peers a consistent response to students who are getting frustrated.

Do Your Makerspace Materials Matter?

In a makerspace, planning out the “stuff” you need definitely feels daunting. In many discussions about school makerspaces, many will assert that the equipment/materials in the space don’t matter and that the atmosphere and mindsets in the space are what truly determine learning success.

While I agree with the latter, I don’t agree with the former. The equipment/materials DO matter, as does the physical space itself (see Sapna Cheryan’s research). Organized materials and the right tools for the job will allow students to develop that critical thinking, tinkering, prototyping mindset and perseverance that are the true desired outcomes of a school makerspace. Hopefully these ideas can help you launch to those ends more easily!

For more, see:

scottie1992

I don't agree

http://nceca.net/wp-content/uploads/2017/02/Preliminary-program-2.01.pdf

Replies

Fillnz

I don’t see how the link provided relates to the topic.

Monica

Hello, I am a year 6/7 teacher from Australia setting up our school's makerspace. Could you please share your school's expectations and common language for your makerspace? Thank you

Replies

Erik Day

Thanks for your comment, Monica. Your best bet for getting in contact with Lindsey is probably through Twitter--you can finder her at twitter.com/LindseyOwn.