Other Machine: Shop Class For The 21st Century

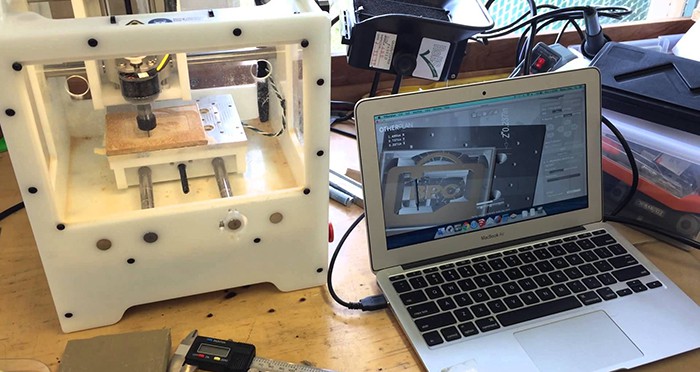

Other Machine Co. (OMC) makes a portable milling machine that makes 2D and 3D objects out of a range of materials (wood, metal, plastic). Like 3D printing, portable computer numerical control (CNC) machines have the potential to, “Democratize manufacturing for individual creators,” said OMC founder and CEO Danielle Applestone.

A tiny fraction of tech startups are women-led, even fewer in manufacturing. In a Popular Mechanics video, Applestone talks about tinkering at home as a kid. Applestone is an MIT grad and went on to earn her doctorate in materials science from the University of Texas.

“Reimagining shop class for the 21st century is very much at the core of why we do what we do,” said Applestone.

At San Francisco’s California College of the Arts (CCA) students use Othermill in their cutting-edge Hybrid Lab, a multidisciplinary creative technology lab that makes tools of engineering accessible to students in art and design. Students prototype circuit boards for computers, and wearables for mechatronics. Instructors said it has lowered the barrier to getting started with electronics.

“Like many others, we had a prototype worth making, but found we were only considered a blip on the radar of manufacturers used to high-volume production,” Applestone told the Economist. She added, “There are very few places where you can get small batches produced especially if your product is not made of bench metal and injection-moulded plastic and circuit boards.”

OMC started shipping product in December and has more than doubled sales each month since then.

Because CCA students can go from drawing board to printed circuit board, “Students are free to experiment with diverse circuit ideas and shapes, enabling them to easily adapt boards to their creative projects,” according to lab manager Andrew Maxwell-Parish who added, “Anyone who has spent significant time doing electronic prototyping loves this machine. It is the type of machine that changes your entire workflow.”

For more on 3d printing, check out:

0 Comments

Leave a Comment

Your email address will not be published. All fields are required.