Student 3D Printing That Helps Make A Difference

By Joy Schwartz

High school can be a challenging time for students. Students often seek security in a future education or career path, or within a social a group of friends. These years are often centered on the self and their personal journey into adulthood.

The truth is, students thrive when asked to solve real problems that have the power to make a difference.

That’s where my journey in 3D printing began. After teaching mathematics and computer science courses for 27 years, I was first exposed to 3D printing technology at a local education conference. I had not explored 3D printing firsthand until our school principal asked if I’d be willing to design and teach our school’s first 3D printing and imaging course.

That’s where my journey in 3D printing began. After teaching mathematics and computer science courses for 27 years, I was first exposed to 3D printing technology at a local education conference. I had not explored 3D printing firsthand until our school principal asked if I’d be willing to design and teach our school’s first 3D printing and imaging course.

I began building our first-semester syllabus with entry-level instruction about imaging with computer-aided design and ending with building and testing functional 3D models.

A typical skill progression one would expect, right?

What made our course special for my students was our goal: we wanted to design and build a working prosthetic to donate to a local seven-year-old girl.

An Ambitious Goal

I had no experience with 3D printing, and maybe that’s why it felt like the best place to start. My students and I would have the opportunity to learn an entirely new skill set together. If we were able to complete the project, we’d be able to experience a powerful moment in the life of someone in need.

Like most educators, I want our graduates to enter the workforce with the ability to solve problems that will make a difference in the lives of others. This was the opportunity to make a lasting impact on my students, and I was ready to give it our best shot. Learning Life Lessons Together

Our Dremel Idea Builder arrived, and we were off to work straight away. Getting started with 3D printing technology was a plug-and-play process. We began by exploring computer-aided design (CAD) at the top of September. Within the next month, we were building and racing cars and building and launching rockets.

Working toward a quickly approaching deadline to complete the prosthetic arm by Christmas, I introduced my students to 3D printed prosthetics through instructional videos. Students explored these resources through Enabling the Future, a global network connecting makers to recipients in need of prosthetics.

Inevitably, designing and building an elbow-actuated prosthetic for seven-year-old Izzy didn’t come without its challenges. However, I made sure to use our mishaps along the way as teaching moments. I guided my students through discussions around what went wrong and how we could proactively prevent the same challenge next time.

Inevitably, designing and building an elbow-actuated prosthetic for seven-year-old Izzy didn’t come without its challenges. However, I made sure to use our mishaps along the way as teaching moments. I guided my students through discussions around what went wrong and how we could proactively prevent the same challenge next time.

On our first of many attempts to print Izzy’s design, we ended up with something that resembled more of a bird’s nest instead of a hand. Sometimes planning and preparation can still create a mess, but I encouraged my students to clean up and try again. Together, my students and I analyzed mishaps that occurred between the design and production process and refined each prototype based upon our hypotheses.

Building Passion for Helping Others

After about 30 hours of printing time for the final design, and a week of classroom time for assembly, the prosthetic arm was complete. Our total cost of consumables for printing and building supplies cost under $50, which we found room for in our classroom budget.

We presented the prosthetic to Izzy together. Students were in awe when watching the adduction and abduction of Izzy’s elbow activated by two connected, string-like filaments that create movement in her fingers. It was an amazing experience like no other.

Since the first successful prosthetic, students at both Hardin-Jefferson High School and West Brook High School have built 13 working prosthetics for children from Texas to Scotland.

Watching my students see a project come to life for the joy of someone else is a truly powerful experience. Unlike typical assignments, the implications of delivering a completed project go far beyond a letter grade, and that intrinsic motivation helps creativity and collaboration flourish in my classroom.

Watching my students see a project come to life for the joy of someone else is a truly powerful experience. Unlike typical assignments, the implications of delivering a completed project go far beyond a letter grade, and that intrinsic motivation helps creativity and collaboration flourish in my classroom.

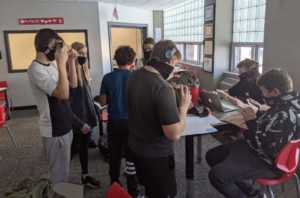

Students learn valuable, lifelong lessons throughout the course of the project. They strengthen their communication and cooperation skills with one another as they share the workload of project tasks. We always encounter obstacles along the way, but students learn to persevere and try again until they reach success.

In a world saturated with media and technology, this program offers students an opportunity to use technology for good. They learn that the skills they gain can make life better for someone else, and they can apply those useful skills today and in the future. To me, that’s the most valuable lesson we can teach our students.

For more, see:

- Other Machine: Shop Class For The 21st Century

- Making Math 3D

- Infographic: 3D Printing, One Step Closer to a Star Trek Future?

Joy Schwartz is a high school computer science and robotics instructor at Beaumont Independent School District, as well as a teacher blogger. Follow her on Twitter: @JoySchwartz

Stay in-the-know with all things EdTech and innovations in learning by signing up to receive the weekly Smart Update.

CCTV Solution

3D printing applications in healthcare do not stop with the human body. They continue with the tools that doctors require for examining and operating on the human body. Surgical tools, like forceps, scalpel handles, and clamps, are able to come out of the printer already sterile–and the materials used are a tenth the cost of stainless steel equivalents.